Forming Capabilities

We have been manufacturing thin-wall rigid containers for over 55 years and proudly offer both injection molding and thermoforming capabilities. Our efficient processes and forming expertise help you reach the market faster—without compromising strength, consistency, or food safety.

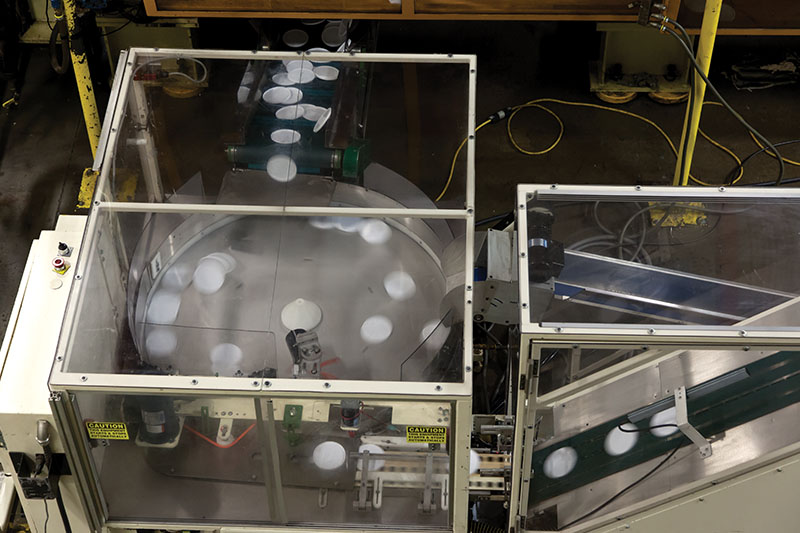

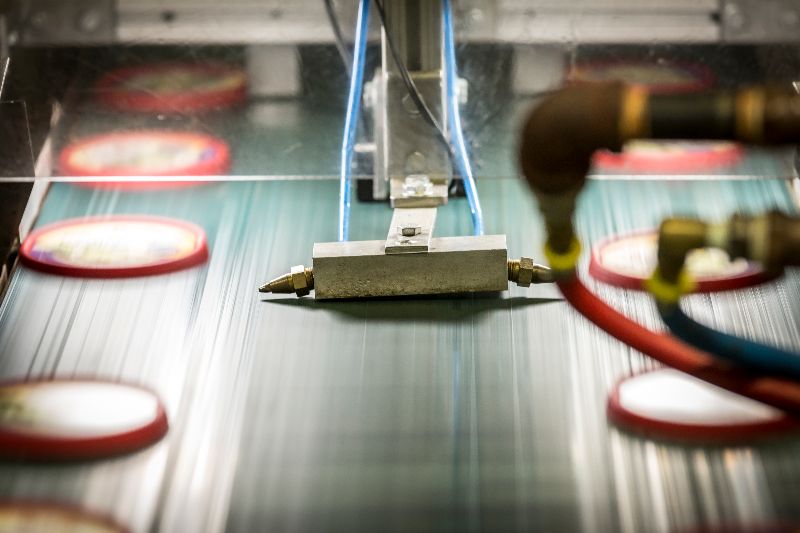

Injection Molding

The forming process involves injecting melted polypropylene into a mold under high pressure, where it solidifies into durable and consistent containers or lids.

The advantage of Polytainers’ proprietary injection molds:

- Decreased wall thickness

- Optimal part weights

- Reduced plastic consumption

- Sustainable designs

- Improved environmental footprint

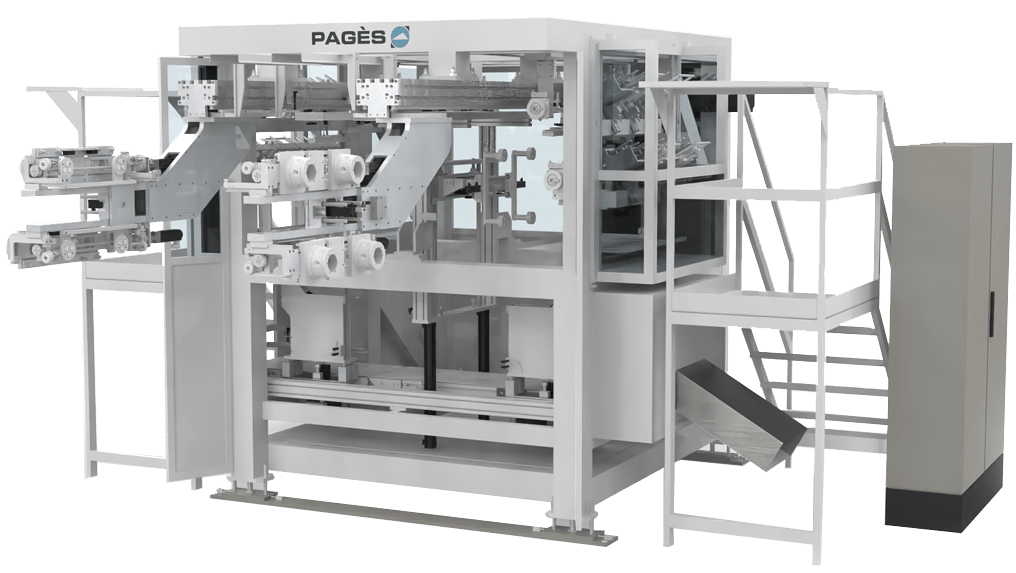

Thermoforming

As North America’s premier deep draw thermoformer, our success is based on moderately sized systems that incorporate the latest forming technology. A plastic sheet is heated until pliable, then formed over a mold to create a lightweight and cost-effective container.

The advantages of thermoforming:

- Reduced part weight

- Ease of light weighting

- Minimal scrap

- Lower total energy cost per pound

- Lower cost

- Improved sustainability

- Shorter tooling lead times

- Faster prototyping