Decorating Capabilities

Award Winning Decorating Capabilities

We are continually innovating, experimenting, and researching the latest trends in packaging decoration from around the world. Our capabilities include in-mold labeling, shrink sleeving and proprietary dry offset printing. Our in-house graphics team has over 50 years of experience and has won over 160 industry awards for superior printing capabilities. Come discover our expertise.

Poly-ToneTM High-Definition Printing (PT-HD)

Polytainers developed Poly-ToneTM HD (PT-HD) in 2012, a proprietary and cost-effective dry offset process. PT-HD produces TruToneTM high-resolution photographic images with the decorating quality of in-mold labeling and shrink sleeving by digitally exposing images directly onto plates resulting in superior quality and productivity.

Both our Lee’s Summit and Toronto facilities are equipped with high-speed PT-HD printers capable of process printing up to 8 colors on both cups and lids.

Advantages

Sharp High Quality Images

Get photographic images that are true to the original with a resolution of 130 LPI.

TruTone™ Color Separation

Get bolder, truer colors than traditional CMYK separations, including spot colors for customers’ logos.

Cost Effective

We have the ability to adjust files on site minimizing downtime on the press and shipping delays.

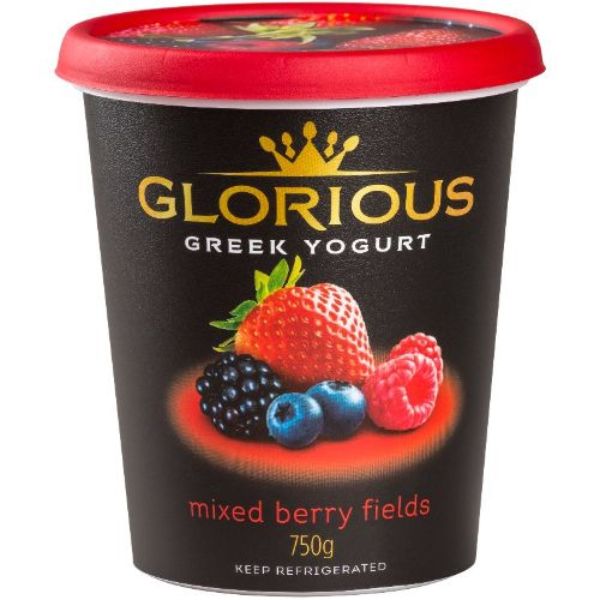

In-Mold Labeling (IML)

The IML process involves robotically placing a pre-printed die-cut polypropylene label into a mold prior to polypropylene being injected thereby fusing the label to the container or lid. The result is a durable, scratch-resistant package decorated with high-quality graphics. Combined with a distinctive opaque or transparent container or lid, the process produces a broad range of appealing design combinations to draw attention to your product.

Polytainers also provides an in-house IML label management program. Contact us to find out more

Advantages

Ultra-Injection Technology

Delivers topload efficiency that surpasses that of standard injection or thermoformed packaging.

Sustainable Designs

Deliver improvement in freight efficiency, weight and resin savings. Improves filler loading efficiency and ergonomics.

Premium Decoration

More Label Area

Shrink Sleeve (SS)

Shrink sleeving involves applying a preprinted plastic sleeve to a container and shrinking the sleeve to conform to the container’s shape. Our shrink sleeve process brings you unique, impactful graphics on packages in a range of shapes that would be difficult to decorate otherwise.

Polytainers also provides an in-house sleeve management program. Contact us to find out more.

Advantages

Versatility

High-End Graphics

Full-Container Decoration

Josh White

Principal

OffWhite Co.

Julia Meck

Founding Partner

Maple Hill Creamery