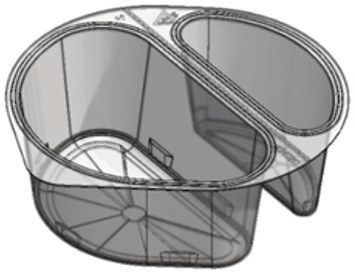

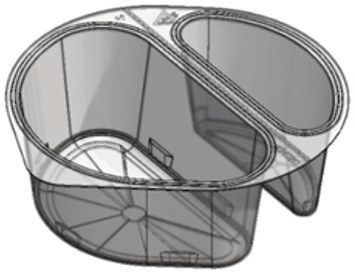

The team began with iterative prototyping and in-depth material testing to optimize the design for consumer usability and manufacturability. Our team used 3D prototypes to assess spoonability and stackability, collaborating closely with the customer to fine-tune compartment volumes. Real-world testing with various particulates ensured adequate headspace for mixing, with multiple rounds of iteration validating the user experience and confirming full spoonability.

As for the challenge of the durable living hinge, Ileana stated,

“We used a specially selected polypropylene material that offered the right balance of flexibility and stiffness, allowing the hinge to bend smoothly without cracking while keeping the compartments securely connected”.

The cup was specifically designed for IML decoration, with a large front panel for bold branding, strong shelf impact, and clear product communication. The label seam was strategically hidden between compartments for a clean, seamless, premium look. In production, the team overcame challenges like plastic flow and cup telescoping by introducing flow leaders, adjusting stacking lugs, and using mold flow simulations to ensure reliable stackability.