History

Polytainers, a privately owned company, has delivered industry-leading plastic packaging solutions since 1968. Guided by the vision of Bob Barrett, the company fosters a culture rooted in curiosity, service, and innovation.

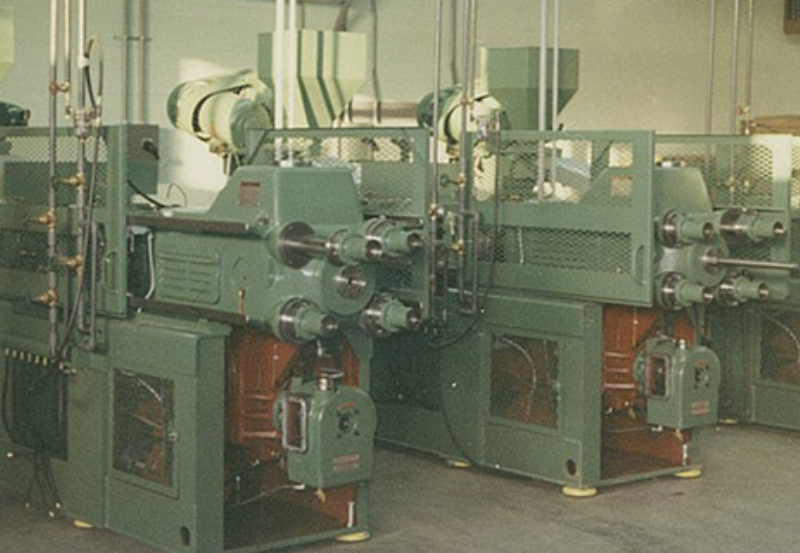

Polytainers commences operations in Toronto. During the first year of business, Polytainers operated 5 days a week in a 9,000 sq. ft. building with three 150 ton molding machines, 2 – 3 color printers and 20 Team Members! In 1968, decorating cups and lids was time consuming because rubber plates…Read More

Prior to SQF (Safe Quality Food) certification, the IMS accreditation was received from State Milk Sanitation Rating Authorities. This signified that we are in satisfactory compliance with the requirements found in the Fabrication of Single-Service Containers and Closures for Milk and Milk Products as governed by the FDA.

We make the move to our current head office/manufacturing location on Norseman Street, Toronto and adopted European technology as a standard. Polytainers’ design capabilities can be linked to European technology. In 1980, we became the first producer of European styled (pedestal) containers in North America.

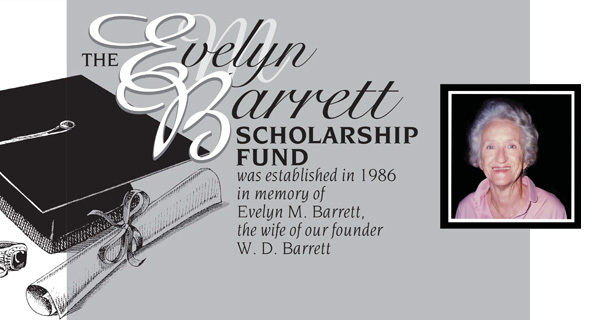

The Evelyn M. Barrett Scholarship Fund was established in memory of Bob’s mother. Two scholarships are awarded annually to daughters or sons of full-time Team Members of Polytainers (Toronto) to help support the cost of their education. Subsequently, the W.D. Barrett Fund was established in 190 providing scholarships in Lee’s…Read More

Our Lee’s Summit, Missouri (Kansas City) facility opens, doubling Polytainers’ capacity and providing operational capability for the U.S. market. The new facility was modeled after our Toronto plant and was located in Lee’s Summit, MO as it’s within 100 miles of the geographic center of the USA. As a result,…Read More

Polytainers spear headed the North American transition of cups made from IM HDPE and TF HIPS to IM polypropylene (PP).

The first eight-color printer was installed in Toronto. Achieving photographic images on a cup is not easy and cannot be accomplished on a press having only six colors. After a number of requests from customers for improved graphics, Bob Barrett urged Van Dam Machine to build what is believed to…Read More

Polytainers expands capabilities with the production of thermoformed (TF) PP containers. Systems employed feature optimal process control resulting in enhanced material distribution and superior container top load.

Pre-press separations moved from an outside source to our in-house Graphics Department. Until 1998, our pre-press separations were done using an outside source. Not only did we become a total solutions provider with the move to in-house separations, but our pre-press process became more effective and efficient. If we aren’t…Read More

Hazard Analysis of Critical Control Points (HACCP) Certification is implemented in both our Toronto and Lee’s Summit facilities. HACCP is a systematic approach to monitoring every step in the food production processes to ensure a safe and wholesome food supply. Prior to HACCP, we relied on a Good Manufacturing Practices…Read More

We become a full-line rigid packaging supplier with the addition of in-mold labelling (IML) and shrink sleeve (SS) application capabilities! We also implemented a strategy to dramatically increase our TF capability.

Polytainers’ undergoes a rebrand and unveils a new logo and tagline (Success You See). The conversion of printing machines from pin bar to magnetic plates commences and PolyToneTMHigh Definition (PT-HD) is introduced to the market. Up until 2012, we used film to expose an image onto plate material and produced…Read More

The Barrett Family Foundation was established in 2013. The Barrett Family Foundation was created by Bob and Francine Barrett as a strategic approach to their philanthropic activities. The Barrett Family Foundation focuses on education, the environment and humanitarian concerns.

Polytainers launched a series of 8, 12 and 16 oz. non-round IML containers! Interest was growing in various categories for non-round packaging largely being driven by the objectives of retailers to improve planogram efficiencies. In support of this growing interest, Polytainers developed a family of stock non-round, display ready packaging…Read More

The Ultimate Series (U Series) of round IML containers in sizes ranging from 8 to 32 ounces is launched! The U Series is a full line of round IML containers that are made with Ultra-Injection Technology and include sustainable designs. These containers offer up to 20% more label height and…Read More

Introduces non-round IML Sidekick (two compartments) square container for yogurt, cottage cheese and snacks. The design of the 5.3 oz. Sidekick container offers a fresh way to snack while optimizing shelf presence. With more full wrap in-mold label area than the leading competitor as well as the option of white…Read More

Throughout 2018, Polytainers celebrated 50 Years of Always Looking Forward! Today, Polytainers operates in the US and Canada with a combined 470k square feet, 120 processing machines and 700 Team Members! Polytainers has flourished on change and through innovation has accelerated its growth and value to customers.

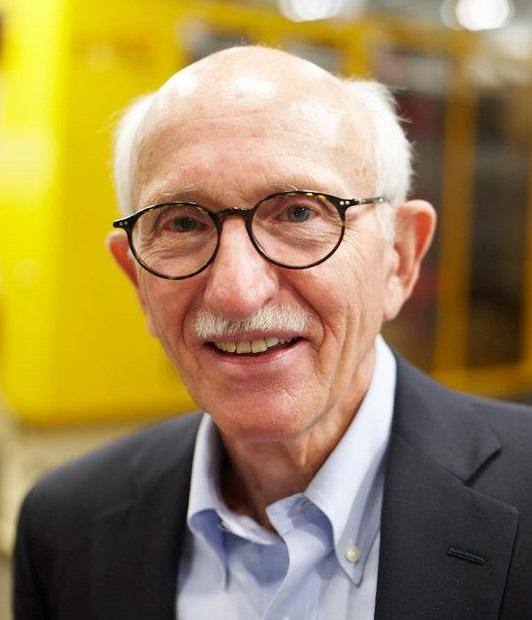

Bob Barrett transitioned to Chairman, focusing on mentorship and the growth of the Barrett Family Foundation, while Susan Dalgleish was promoted to President and CEO. The company expanded from a founder-led to a professionally managed organization, adding leadership roles in Supply Chain, Procurement & Sustainability, Plant Operations, and IT, while…Read More

In celebration of 55 years of innovation and growth, Polytainers hosted a fun-filled day of games, food, and community at both facilities. It was an unforgettable event that brought together team members and their families in appreciation of the people behind our success.